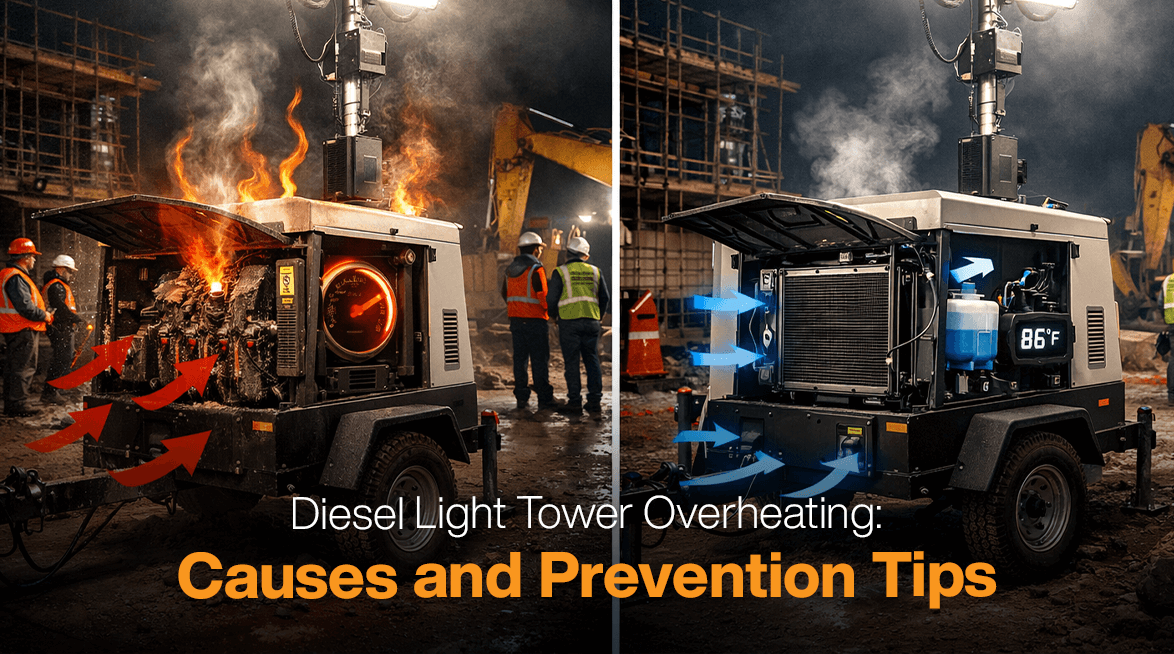

Diesel-powered equipment is designed to perform in challenging environments, whether it is a construction site, a mining site, an infrastructure project, or in an emergency response zone. One of them is diesel light towers, which are quite helpful in offering reliable lighting where electricity is either nonexistent or insufficient. However, overheating is among the performance issues that site operators and fleet owners must constantly address.

The phenomenon of overheating is not only a minor inconvenience, but it can also lead to unpredictable breakdowns, reduced fuel efficiency, increased maintenance costs, and even permanent engine damage.

This blog investigates the main causes of diesel light tower overheating and provides practical tips to ensure your equipment runs efficiently.

Why Overheating is a Serious Concern in Diesel Light Towers

Diesel engines are designed to handle heavy loads, but they operate within strict temperature limits. Beyond this range, engine components such as cylinders, gaskets, and lubricants begin to wear out quickly.

The wear of engine components increases due to reliance on diesel equipment. The global market of diesel generators, as well as diesel light towers, among others, is projected to reach USD 20.84 billion in 2024 and USD 37.03 billion by 2032. This growth reflects a deepening dependence on diesel-based solutions in the construction, industrial, infrastructure, and emergency response industries.

With the ever-growing use of diesel light towers, simple overheating may cause the following:

- Unplanned shutdowns during critical nighttime operations

- Shortened life of the engines and increased cost of repairs.

- Increase in fuel consumption and emissions.

- Operational and equipment safety risks.

Since light towers tend to operate for long hours, even in unfavorable weather conditions, it is even more important to control engine temperatures.

Common Causes of Diesel Light Tower Overheating

1. Insufficient Cooling System Maintenance

The initial defense mechanism against overheating is the cooling system. Radiators may get blocked with dust, debris, and oil residues, particularly on construction and mining sites.

Heat dissipation is also seriously impaired by low coolant levels, leaks, or the use of improper coolant mixtures. When heat cannot be transferred efficiently away from the engine, temperatures rise rapidly.

2. Blocked or Restricted Airflow

Diesel light towers heavily rely on airflow to regulate engine temperature. Heat can be trapped by blocked air intakes, dirty radiator fins, or poor ventilation of the unit.

This problem occurs when light towers are positioned too close to the wall, equipment, or temporary enclosures. Even well-designed machines will overheat if their “breathing” space is restricted.

3. Overloading the Light Tower

Operating a generator at a higher capacity than the rated one puts undue pressure on the engine. Overloading increases the temperature of combustion and strains the cooling system more than it is supposed to be.

This often happens when additional equipment is connected without considering load limits, or when ageing components reduce the generator’s effective capacity.

4. Poor Fuel Quality

Diesel fuel with low or low-quality might also result in incomplete combustion. This will lead to an increase in exhaust temperatures, carbon accumulation, and inefficient engine performance, all of which cause overheating.

The impurities in the fuel may also affect the injectors and filters, resulting in increased pressure on the engine and higher operating temperatures.

5. Extreme Environmental Conditions

Diesel Light towers are often used in hot, dusty or damp areas. High ambient temperature decreases the efficiency of heat exchange in radiators, while dust accumulation accelerates clogging.

The risk of overheating is high when working in extreme climatic conditions without prior design considerations and preventive maintenance.

Prevention Tips to Avoid Diesel Light Tower Overheating

1. Ensure Proper Ventilation and Placement

Diesel light towers should always be placed in the open space with enough clearance around the air intake and exhaust points. Units should not be installed in areas with impediments that limit air movement.

If it is necessary to work in very tight areas, additional ventilation efforts should be made to cool the air.

2. Monitor Load Levels Closely

One of the easiest but most effective measures to avoid overheating is operating with the recommended load capacity. Monitoring systems or using load indicators help ensure that the generator is not being overloaded.

The balanced load control ensures the generation of less heat as well as better fuel efficiency and engine life.

3. Use High-Quality Fuel and Filters

Top diesel light tower manufacturers, like Olikara, also encourage efficient engine performance by incorporating all essential maintenance services, including the use of clean and high-quality diesel and changing fuel filters. This enhances effective burning and safe operational temperatures.

To maintain optimal engine performance, it is crucial to replace the fuel filters on schedule. This proactive maintenance strategy helps prevent contaminants from entering the engine, reducing the long-term risk of overheating and ensuring reliable operation.

4. Invest in Advanced Cooling and Monitoring Features

The recent diesel light towers are introducing more advanced cooling systems, temperature sensors, and automatic shutdown systems. These characteristics offer timely notifications and avoid disastrous malfunctions.

Selecting equipment from manufacturers familiar with thermal management can attain a difference in uptime and reliability.

5. Train Operators to Recognize Early Warning Signs

There are rare instances when overheating occurs unexpectedly. An increase in temperature indicators, odd sounds, loss of power, or frequent power outages are all warning signals.

Well-trained operators can react quickly to a situation, either by reducing the load or by closing the unit, prior to small problems turning into big failures.

The Role of Quality Engineering in Preventing Overheating

At Olikara, diesel light towers are engineered with a clear focus on thermal efficiency and long-term reliability. Every unit is designed to operate within safe temperature limits, even in demanding site conditions, through thoughtful engineering and precision manufacturing.

Olikara features a high-efficiency cooling system designed to effectively dissipate heat and maintain optimal engine performance, even during extended operation. The enclosures are engineered to provide robust protection while ensuring optimal airflow for proper ventilation. Additionally, the engines are precisely calibrated to the generator and lighting loads, eliminating power wastage and preventing unnecessary strain on critical components.

These engineering principles demonstrate Olikara’s commitment to offering diesel light towers that ensure consistent performance and minimize overheating risks.

Conclusion

Overheating is one of the most common yet preventable problems of diesel light towers. Through proper maintenance and understanding its underlying causes, businesses can enhance reliability and performance.

Thoughtful engineering is all that matters at the design and manufacturing level. Olikara Lighting Towers, your ultimate diesel light tower manufacturer, combines solid construction, effective cooling mechanisms, and industry-oriented innovation to provide diesel light towers that can be relied on in difficult situations.

FAQs

1. What is the most common cause of overheating of diesel light towers?

Improper maintenance of cooling systems and restrictions of the airflow, especially in dusty and hot conditions, are the most prevalent causes.

2. How many times should the diesel light towers be serviced to prevent overheating?

They must be examined weekly and serviced per the manufacturer’s instructions or based on the service schedule.

3. Can a diesel light tower be overheated by being overloaded?

It is, however, a fact that operating above load will result in excess strain on the engine as well as combustion heat, which will lead to excessively high temperatures.

4. Are the recent diesel light towers resistant to overheating?

Many developed models are equipped with temperature sensors and automatic shutdown functions to avoid excessive damage to the engine due to overheating.