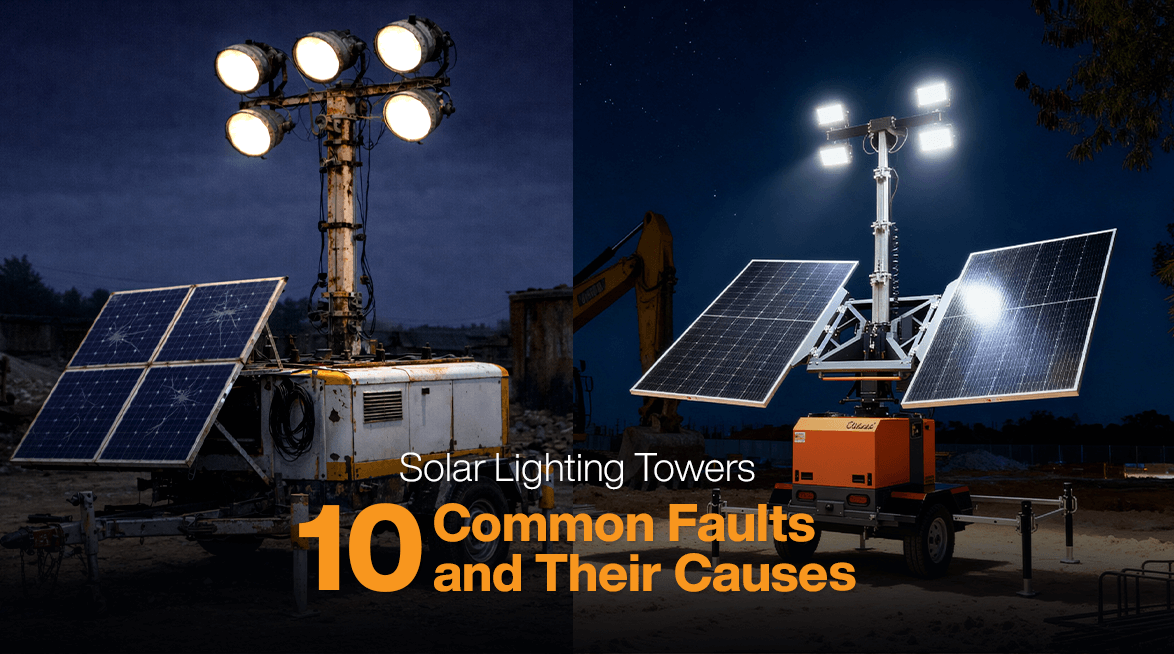

With the growth of infrastructure projects, sustainability no longer remains a buzzword; it becomes a duty. At construction sites, mining locations, highways, disaster relief missions, and huge outdoor events, the solar-powered lighting solutions are quickly overtaking the diesel systems. The Solar Light Tower is a cost-effective, environmentally friendly, and adaptable solution in terms of its scope of use.

Nevertheless, similar to any sophisticated system that incorporates photovoltaics, batteries, electronics, and mechanical parts, Solar-Powered Light Towers are not immune to faults. Being aware of those faults and their underlying causes will assist project managers in making informed decisions, minimizing downtime, and extending the life of equipment.

Let’s explore 10 common faults in Solar Light Towers and why they occur.

Why Understanding Solar Light Tower Faults Matters

When a lighting tower malfunctions, the impact goes beyond inconvenience. Poor visibility may stop operations, cause accidents, postpone project schedules, and raise operating expenses. Awareness of these flaws serves as a guide to smarter buying among buyers assessing either Solar Light Tower manufacturers or Solar Light Tower suppliers. (5 examples of Olikara)

1. Insufficient Illumination Output

The Fault

The tower is switched on; however, the light illumination is poor or patchy.

Root Causes

- LED lamps with low lumens to minimize initial investments

- Lack of height in the mast design restricts the spread of light

- Wrong angle of beam setup

- Dust accumulation on lenses

Why It Happens

Other manufacturers are willing to compromise on optical design or the quality of LEDs. Poor thermal management also reduces the efficiency of the LED over time.

How Quality Design Prevents It

Properly designed towers incorporate high-lumen LEDs, reflector angles that are optimized, and sufficient mast height to provide uniform lighting over extensive distances. For example, the Qube Power, from the Engine-Powered range of Olikara, consists of 4 x 200 W LED, which provides a light coverage of 4000 sq. m.

2. Battery Drains Faster Than Expected

The Fault

The Solar Light Tower shuts down before the end of the night.

Root Causes

- Small battery capacity

- Poor-quality cell batteries

- Wastage of power by inefficient components

- Incorrect programming of battery charge-discharge cycles

Why It Happens

Not every battery is built to be used deep-cycle outdoors. Lithium or lead-acid cheap batteries lose capacity rapidly at high temperatures.

Best Practice

Manufacturers of reputable Solar Light Towers incorporate industrial-grade batteries and smart energy management systems to provide overnight independence even on low-sun days.

3. Solar Panels Not Charging Efficiently

The Fault

Panels are intact, yet the charging is slow and inconsistent.

Root Causes

- Dust, mud, or debris buildup

- Shadings caused by adjacent equipment

- Incorrect tilt angle

- Micro-cracks in solar cells

Why It Happens

Temporary sites tend to expose the panels to adverse environments. The problem is aggravated by inappropriate placement of panels when deployed.

Engineering Insight

To ensure that the solar power is still charged, Advanced Solar Light Towers are built with an optimal panel tilt, simple-to-clean surfaces, and solid mounting frameworks. For example, the Qube Solar from the Hybrid -Powered range of Olikara consists of 4 x 200 W LED, which provides a light coverage of 4000 sq. m.

4. Mast Lifting or Tilting Mechanism Failure

The Fault

The mast does not extend, retract, or lock correctly.

Major Causes

- Low-quality hydraulic or manual winch systems

- Rust or corrosion

- Overloading beyond design limits

- Lack of regular lubrication

Why It Happens

Cheap mechanical parts might not be able to sustain repeated cycles in harsh conditions.

Smarter Design Advantage

Good-quality towers incorporate tested lifting mechanisms and stainless steel materials, which make the mast operation safe and easy over the years of utilization.

5. Controller or Inverter Malfunction

The Fault

System powers on inconsistently or shuts down randomly.

Causes

- Electronic components overheating

- Voltage mismatch

- Moisture ingress

- Substandard wiring

Why It Happens

Electronic parts are somehow ignored in procurement, but they are the brain of the Solar-Powered Light Tower.

Prevention Strategy

Proper heat dissipation, certified electrical components, and weather-sealed control panels are seen on well-built towers.

6. Lights Flicker or Fail Completely

The Fault

Lights flicker intermittently or stop functioning.

Root Causes

- Loose wiring connections

- LED driver failure

- Power surges

- Water intrusion in fixtures

Why It Happens

Outdoor environments are unforgiving. Low-grade connectors or poor sealing speed up failures.

Reliable Solution

Suppliers of Professional Solar Light Tower focus on IP-rated lighting fixtures and strong cabling that is safe to use in extreme outdoor environments.

7. Reduced Performance in Harsh Weather Conditions

The Fault

Lighting duration shortens during cloudy or rainy seasons.

Causes

- Inadequate panel capacity

- Weak energy storage strategy

- Absence of hybrid backup facilities

- Inefficient charge controllers

Why It Happens

There are systems that have been designed based on ideal sunlight conditions that are hardly applicable in the real world.

Industry Insight

Modern Solar Light Towers are being designed with energy buffers that manage seasonal solar variability without reducing functionality. For example, the Qube Power Max Hybrid from Hybrid -Powered range of Olikara, consists of 6x 200 W LED, which provides a light coverage of 4000 sq. m.

8. Structural Instability in High Winds

The Fault

The tower is swaying, leaning, or on the verge of falling.

Major Causes

- Lightweight chassis

- Inadequate outriggers

- Poor center-of-gravity design

- Poor use on uneven surfaces

Why It Happens

Structural integrity is sometimes compromised with mobility-oriented designs.

Design That Matters

Stability-oriented engineering makes sure that the operation is safe even in unstable terrains, which is crucial in the case of highway and infrastructure projects.

9. Excessive Maintenance Requirements

The Fault

The tower needs regular repairs or replacement of parts.

Root Causes

- Inferior material quality

- Non-standard spare parts

- Complex system design

- Poor after-sales support

Why It Happens

Not every manufacturer of Solar Light tower considers lifecycle cost; some concentrate on initial pricing.

Long-Term Perspective

Good manufacturers make low maintenance and standardization/ easy servicing designs, which save money in the lifetime of the equipment. For example, the Qube Grid base / trailer from the Grid-Powered range of Olikara consists of 4 x 400W LED and also has light coverage of 6000 sq. m.

10. Short Overall Lifespan

The Fault

The Solar Light Tower cannot be trusted after a few years.

Root Causes

- Weak component integration.

- Lack of weatherproofing

- Poor manufacturing standards.

- Absence of quality testing

Why It Happens

Solar lighting systems must operate outdoors for years. Lifespan is significantly affected negatively by any compromise made in the manufacturing process.

Smart Procurement Insight

By selecting a supplier with experience in Solar Light Tower, it will be guaranteed that the system is constructed to endure the stress of actual operation rather than those in the showroom.

Choosing the Right Solar Light Tower: What Buyers Should Look For

Understanding faults is only half the solution. They should be prevented during the buying stage. The decision-makers must consider:

- Components quality (LEDs, batteries, panels, controllers)

- Structural stability and design engineering.

- Seasonal consistency in performance.

- After-sales support and service.

- Experience of the manufacturer in large-scale deployments.

The right Solar Light Tower can be a dependable asset when considered as a whole instead of being a recurring cost.

Also Read: Why Solar Light Towers Are the Smart Choice for Outdoor Lighting?

Conclusion

Solar lighting towers are the future of temporary and mobile lighting- clean, noiseless, and economical. But their success relies on careful engineering, good production, and practical testing. Knowing the 10 most common faults and their causes, customers can prevent operational disruption and get the best out of long-term value.

At Olikara Lighting Towers, design decisions are not influenced by assumptions but by on-ground realities, which guarantee reliability, durability, and uniform performance across challenging applications. For organizations that need reliable solar lighting solutions, the right manufacturing partner can make a difference.

FAQs

- What is the most common fault in a Solar-Powered Light Tower?

The most frequent are battery-related problems, typically due to having a small capacity or a poor-quality cell not designed to be used outside.

- What is the projected life of a Solar Light Tower?

A Solar Light Tower with quality parts and good maintenance can work up to 8-10 years or even longer.

- Can solar light towers be used in cloudy or rainy seasons?

Yes, well-designed systems store enough energy and are designed to work even in low-sun conditions.

- How do I choose reliable Solar Light Tower suppliers?

Seek established industry experience, solid engineering skills, certified parts, and reliable after-sales services.